A common scale on a machinist’s rule is an indispensable tool for precision measurements in various industries. From engineering to manufacturing, these scales provide accurate and reliable measurements, enabling professionals to create and maintain high-quality products.

In this comprehensive guide, we will explore the different types of common scales found on a machinist’s rule, their applications, and the factors affecting their accuracy and precision. We will also provide practical tips on reading, interpreting, and maintaining these scales to ensure optimal performance and longevity.

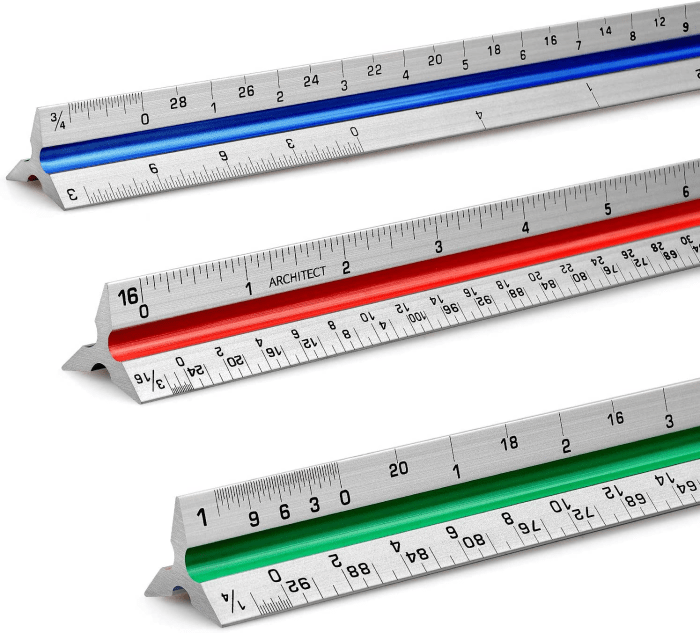

Types of Common Scales on a Machinist’s Rule

A machinist’s rule is a versatile measuring tool used in various industries. It typically features several common scales, each with its unique characteristics and applications.

Inch Scale

- Divided into inches and fractions of inches

- Commonly used in the United States and Canada

- Advantages: Simple to read and interpret, widely recognized

- Disadvantages: Limited precision compared to other scales

Metric Scale

- Divided into millimeters and centimeters

- Used internationally and in scientific applications

- Advantages: High precision, allows for easy conversion between units

- Disadvantages: May require more familiarity for those accustomed to inch scales

Vernier Scale

- Attached to a movable slide that aligns with the main scale

- Allows for precise measurements to a fraction of the smallest division on the main scale

- Advantages: Extremely accurate, ideal for detailed work

- Disadvantages: Requires careful alignment and interpretation

Applications of Common Scales on a Machinist’s Rule

Common scales on a machinist’s rule find applications in a wide range of industries:

Engineering and Manufacturing

- Measuring dimensions of components and assemblies

- Setting up and calibrating machinery

- Inspecting parts for accuracy and tolerances

Construction, A common scale on a machinist’s rule is

- Measuring distances and angles

- Laying out and leveling structures

- Checking dimensions of building materials

Science and Research

- Measuring specimens and materials

- Calibrating scientific instruments

- Conducting experiments and recording data

Accuracy and Precision of Common Scales on a Machinist’s Rule

The accuracy and precision of common scales on a machinist’s rule are crucial for reliable measurements:

Accuracy

- Refers to the closeness of a measurement to its true value

- Affected by factors such as scale calibration, reading errors, and environmental conditions

Precision

- Refers to the consistency of repeated measurements

- Affected by factors such as scale resolution, operator skill, and measurement technique

Tips to ensure accuracy and precision:

- Use a calibrated rule and check its accuracy regularly

- Read the scale carefully and align it perpendicular to the object being measured

- Estimate the measurement before reading the scale to avoid parallax errors

Reading and Interpreting Common Scales on a Machinist’s Rule: A Common Scale On A Machinist’s Rule Is

Reading and interpreting common scales on a machinist’s rule requires careful attention:

Inch Scale

- Read the whole inches marked on the scale

- Estimate the fraction of an inch by dividing the space between the inch marks

- For example, if the measurement falls between 3 and 4 inches, estimate it as 3.5 inches

Metric Scale

- Read the whole centimeters marked on the scale

- Estimate the fraction of a centimeter by dividing the space between the centimeter marks

- For example, if the measurement falls between 10 and 11 centimeters, estimate it as 10.5 centimeters

Vernier Scale

- Align the zero mark of the vernier scale with a mark on the main scale

- Count the number of divisions on the vernier scale that coincide with divisions on the main scale

- Multiply the count by the vernier scale’s resolution to obtain the fractional part of the measurement

Maintenance and Care of Common Scales on a Machinist’s Rule

Proper maintenance and care ensure the longevity and accuracy of common scales on a machinist’s rule:

Cleaning

- Wipe the scale regularly with a soft cloth

- Use a mild cleaning solution if necessary

- Avoid using abrasive cleaners or solvents

Lubrication

- Apply a thin film of light oil to the movable parts of the rule

- Lubricate the rule periodically or as per manufacturer’s instructions

- Excess oil can attract dirt and affect accuracy

Storage

- Store the rule in a dry, dust-free environment

- Avoid exposing it to extreme temperatures or moisture

- Keep the rule protected from impacts or bending

Q&A

What are the most common types of scales found on a machinist’s rule?

The most common types of scales found on a machinist’s rule include the inch scale, metric scale, and vernier scale.

How do I read measurements on a machinist’s rule accurately?

To read measurements accurately on a machinist’s rule, align the zero mark of the rule with the starting point of the measurement and read the value at the point where the desired measurement ends.

What factors can affect the accuracy of measurements made with a machinist’s rule?

Factors that can affect the accuracy of measurements made with a machinist’s rule include temperature variations, wear and tear, and improper calibration.